The ABiCo – Advanced biocomposites with Circular Design – project aims to develop innovative high-performance biobased biocomposite solutions to replace fossil-based primary raw materials. It will increase the use of recycled polymers and biobased raw materials in new demanding applications in accordance with the principles of the circular economy.

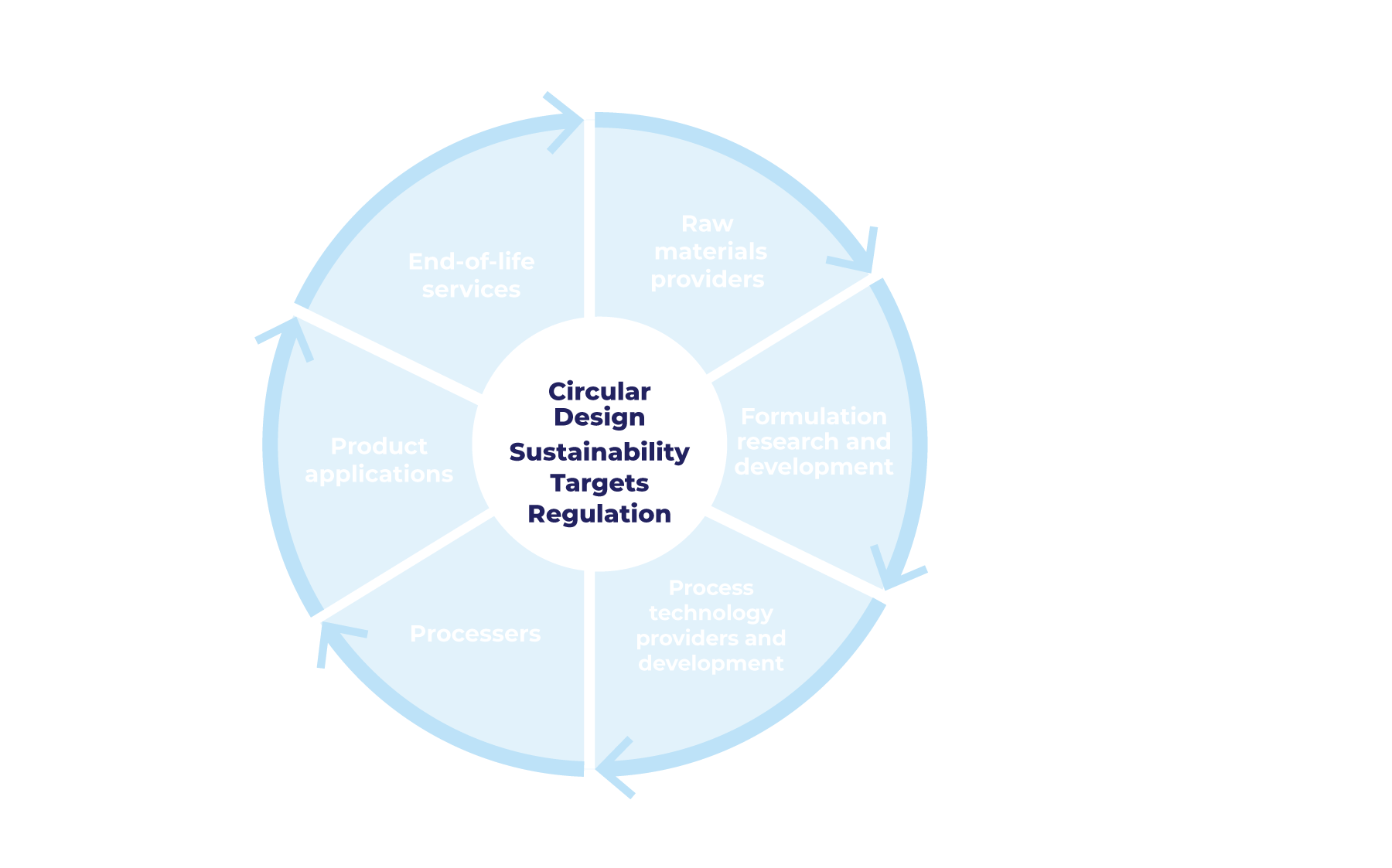

ABiCo catalyses cross-disciplinary research, innovation capacity and development of sustainable bio-based innovations, integrating sustainability throughout the innovation chain.

Global and EU-level regulations for improved sustainability in material origin and improved circulation potential are the main drivers towards biocomposites, which are to some extent already in use, e.g., end-use applications in construction, automotive and many consumer products.

A large proportion of composites are currently made from fossil-based raw materials -> There is a need and demand to use also raw materials from other sources.

Biocomposites have been available on the market for decades, but their use has been restricted to limited application areas due to their current performance levels and processability. Now, many industrial areas and brand owners around the world are demanding biocomposites that have better performance levels, suitable for high quality products.

Companies are searching for more sustainable alternatives to plastics and composites.

ABiCo was initiated based on these business needs.

Biobased fibres, additives, and recycled polymers enable a significant reduction in emissions while also enhancing the competitiveness of businesses and creating opportunities for new business

Biocomposites are not currently recycled as material and their main end-use is energy recovery. There are recyclability bottlenecks in collection logistics, identification and separation, and novel uses of recycled biocomposite material.

Limitations include not being fully compatible with current industrial processing, not being able to fully meet target application requirements such as flame retardance, and/or their higher cost vs existing solutions.

Key challenges with biocomposites are their structural and functional behaviour, identification of raw materials for recycling, extraction processes, sustainable feedstock, implementation of biocomposite interfacial properties, material processing and product manufacturing, and safe service life and product design.

The ABiCo project is funded by the Business Finland “Expand Fibre” ecosystem.

Project timeline: 8/2024–8/2026